PRECISION MACHINED SPROCKETS

High quality precision machined sprockets reduces down time!

Pennine have specialised in the manufacture of Silent Chain Sprockets for over 30 years and offer a wide range, all of which are produced in our own workshop. Pennine can manufacture sprockets with any number of teeth or bore size. Unless otherwise specified, all Pennine sprockets are cut with an ANSI standard tooth profile. Sprockets are manufactured from either 080M40 or 080A42 carbon steel with flame or induction hardened teeth or from SG600 Cast Iron. There are three main types of sprocket available.

Centre Guide Sprockets are supplied with a 5mm wide groove in the centre of the sprocket tooth width to locate the guide links, and have a 15 degree angle on each side of the groove to improve the entry of the guide links into the groove.

Side Guide Sprockets have no grooves but the outer edge of the teeth have a 15 degree angle on them to improve entry. To maintain a long and trouble free chain life it is essential that sprockets are correctly aligned and have the correct tooth form. If the sprockets being used are not manufactured by Pennine, then we cannot guarantee chain life or honour any warranties.

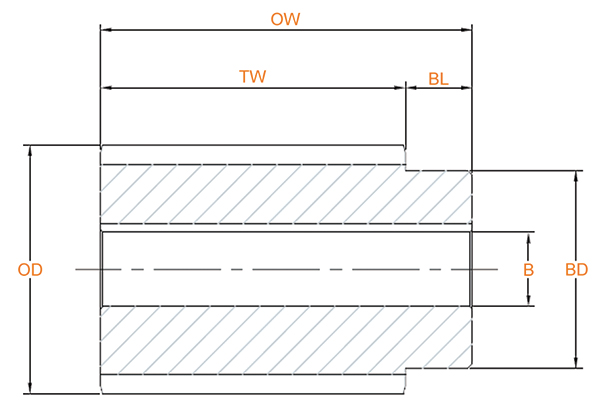

- Guide type (Centre, Side or Multi-Guide).

- Face width.

- Keyway size.

- Boss Projection.

- Boss Diameter.

- Number of Teeth.

- Bore Diameter.

- Boss Type.

- TW – Tooth Width

- B – Bore

- OD – Outside Diameter

- BD – Boss Diameter

- OW – Overall Width

- BL – Boss Length