ENGINEERED PLASTICS

Pennine Industrial Equipment manufacture and stock a wide range of plastic machined components, utilising a comprehensive range of materials, covering a vast range of applications. We use state of the art CNC machinery alongside the latest CAD / CAM design and programming software.

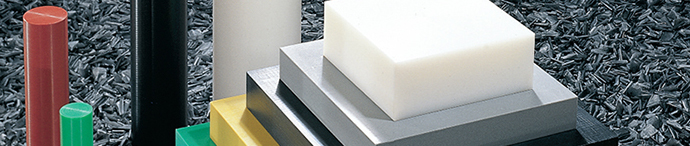

Sheet & Rod

Stocking a vast range of raw material to suit your application needs

Pennine stock a large range of raw material in both sheet and rod form. Sheets are stocked from 2 mm thick up to 70 mm thick, in a variety of grades (some of which are detailed below).

1000 Grade UHMW-Pe (food grade)

- ST1000 White

- ST1000 Blue

- ST1000 Green

- Prem-Lube (Self Lubricating)

- Prem-Detect (Metal Detectable)

Regenerated UHMW-Pe

- A4G (Green)

- A4B (Black)

- A4M (Multi-Coloured)

Contact our Sales Team for a full technical specification and recommendation on the correct material for your application.